Quickly and easily print, cut, batch, and stack care labels right from your manufacturing facility. The SNAP™ 500 printer enables businesses to process a variety of care and content labels that meet the unique needs and requirements of each customer in a single, high-speed operation.

Our customers use the multiheaded SNAP 500 to print care labels with the fire warning in red.

Two-sided print capability: Increases fabric utilization for reduced costs when designing sewn-in care labels.

Prints on range of materials: Coated polyester, nylon, satin weave, and heat seal.

Easy-to-use: Hassle-free controls, quick stock loading, and a center-justified feed path that minimizes operator attention, training, and printer downtime.

Decreased downtime: Voice prompts and a virtual control panel simplify adjustments.

Remote diagnostics, Internet-based operating system upgrades, and intuitive consumable replacement reduce maintenance time.

Pre-installed cold-knife and stacker: Product a fininshed label at no extra cost. For coated labels, no need for heat of sonics.

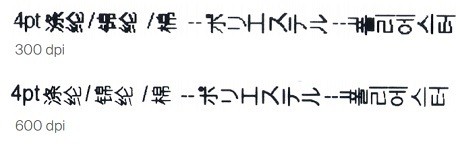

600 dpi printhead (optional): Allows for higher resolution printing.

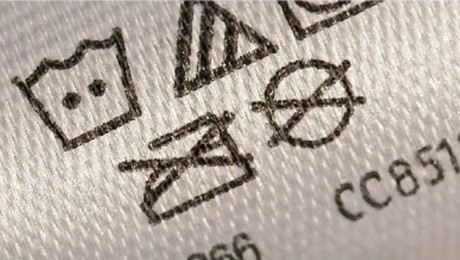

Sewn-in information: Meet legal, retail, factory tracking, and customs compliance with timely and accurate information. Provide consumers with a permanent reference of garment attributes.

Alternative to Sewn-in: Heat seal labels to shoes and other apparel not suitable for sewn-in labels.

Tracking: Attach real-time, garment specific labels, including lot number, garment serial number, and production data. Use for factory information or post-sale compliance requirements such as CPSIA.

High Content Care Labels: The 600 dpi printhead allows more legible printing of smaller characters, shrinking the label size.

The SNAP 500 Sonic Knife uses ultrasonic vibrations to cut uncoated woven labels. Heat generated from the vibrations seal the label ends on a microscopic level. The result is a luxurious printed label that is soft to the touch with a premium look and feel.

The Sonic Knife integrates easily with the SNAP 500, receiving a cut signal and cut adjustments from printer. No sensemark is required. The labels drop onto the SNAP down stacker which attaches to the sonic knife as it would the SNAP 500 itself.

A separate power supply provides the ultrasonic vibrations that cut the labels.

This option includes an oven that heats a heat-set woven polyester fabric called LOKPRINT™ tape. Heating the tape causes the dye-sublimation ink to vaporize while the polyester fibers open up to absorb the ink.

The result from the SNAP 500 LOKPRINT is a soft, luxurious care label with an image permanently fixed into the yarns that will withstand harsh denim and industrial enzyme washes.

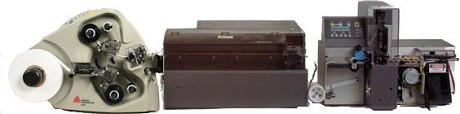

The LOKPRINT system shown below includes the SNAP 500 printer, LOKPRINT adapter, 2-sided LOKPRINT oven, and Sonic Finishing station.

For ultra-high definition printing, the 600 DPI-enhanced printhead resolution provide legible Asian and Eastern characters, fitting more content on less label.

Use of the 600dpi is not recommended for all applications. The printhead is more expensive and wears out at the same rate as 300dpi. Therefore, only use 600dpi printing for applications that call for higher resolution.

Get specific details about this product from customers who own it.

Rating

Price

Tk. 0

Tk. 0

Tk. 0

Tk. 0

Model

Avery Denisson Snap 500

MH-361T

Zebra 170Xi4

NOVEXX 6406

Brand

Avery Dennison

TSC

Zebra

Novexx Solutions

Print technology

Workload

Application

Resolutions

Maximum Print Speed

Memory

Firmware

Label Media

Riboon Media

Standard connectivity

Features

Have question about this product? Get specific details about this product from expert.

Get specific details about this product from customers who own it.